Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

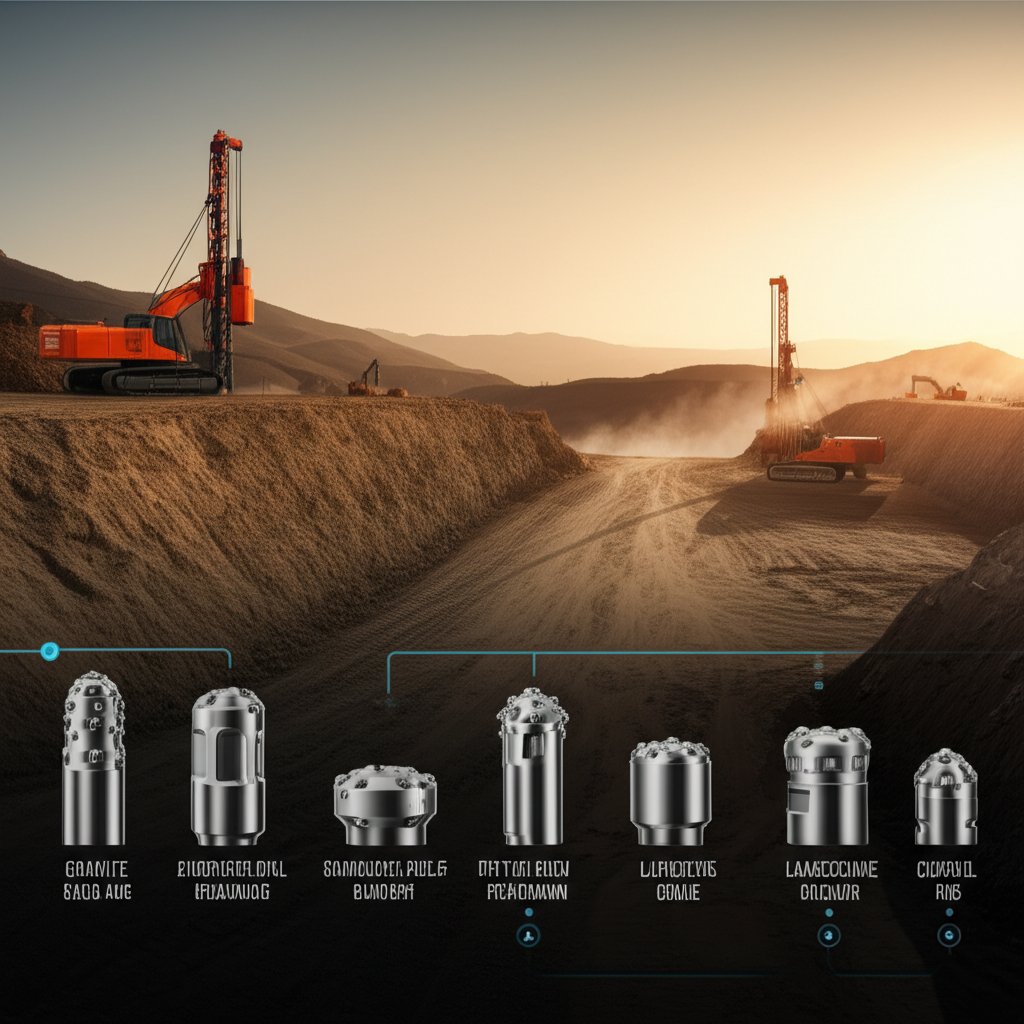

Imagine standing at the edge of a massive construction site or deep within a mining operation. What’s the one tool that keeps progress moving beneath your feet? The answer: the button bit. These specialized drill bits are the silent workhorses that power some of the world’s most demanding industries—mining, construction, geothermal drilling, and beyond.

At its core, a button bit is a type of rock drilling tool engineered to break, crush, and remove rock efficiently. The "button" in its name refers to the robust tungsten carbide or steel inserts—small, round protrusions—strategically placed on the bit’s surface. These buttons are the primary cutting elements, designed to withstand extreme impact and abrasion as they bore through everything from soft sediment to the hardest rock formations.

Button bits are most commonly used in rotary and percussive drilling systems. Their unique design ensures maximum contact with the rock surface, allowing for efficient energy transfer and rapid penetration. Whether you’re drilling for minerals, laying foundations, or tapping into geothermal energy, the right bit button is crucial for both speed and precision.

"Button bits are the backbone of most drilling operations, engineered to withstand extreme conditions and deliver consistent performance, making them essential for achieving project objectives safely and efficiently."

Why do professionals rely so heavily on button bits? The answer lies in their durability, versatility, and ability to adapt to a wide range of geological challenges. With advancements in materials and face design, today’s button bits can tackle harder rocks, last longer, and help control project costs by reducing downtime and maintenance needs. In an industry where every minute counts, having the right drilling tool can make all the difference between hitting a project deadline or falling behind.

As you’ll discover in the chapters ahead, understanding how to select, maintain, and maximize the performance of your button bit is key to unlocking efficiency and success in any drilling project.

Ever wondered what makes a button bit so resilient in the face of solid rock? It’s not just brute force—it’s smart engineering. Let’s take a closer look at the inner workings of a button bit and see how each component contributes to its legendary performance in drilling operations.

Picture a cross-section diagram of a button bit: robust steel at the core, studded with tough tungsten carbide buttons, intricate face patterns, and carefully placed grooves for debris removal. Each element is carefully designed for maximum efficiency and durability. Here’s how it all comes together:

Bit Body (Steel Quality): The backbone of any button bit is its body, typically forged from high-grade alloy steel. This steel must be tough enough to absorb the intense percussive forces of drilling while resisting fatigue and deformation. High-quality steel ensures the bit maintains its shape and integrity even after repeated impacts, directly affecting the lifespan and reliability of the tool.

Tungsten Carbide Buttons (Cutting Elements): These are the "buttons" that give the bit its name. Made from ultra-hard tungsten carbide, these inserts are engineered to crush and fracture rock with every rotation and blow. Depending on the application, the buttons can be spherical, ballistic, or conical in shape—each optimized for different rock types and drilling strategies. Their precise placement across the bit face ensures even wear and consistent penetration rates.

Face Design: The arrangement and contour of the bit’s face play a critical role in how it interacts with the rock. Some faces are flat for stability in hard formations, while others feature drop centers or concave shapes to improve tracking and debris evacuation. The face design also determines how the force is distributed across the buttons, impacting both drilling speed and bit longevity. Innovative face designs, developed through advanced engineering, continue to push the limits of what button bits can achieve in the field.

Flushing Holes and Grooves: Drilling generates heat and a lot of rock debris. To keep the bit cool and the hole clear, button bits incorporate a network of flushing holes and grooves. These channels allow high-pressure air or drilling fluid to flow through the bit, efficiently removing cuttings from the borehole and reducing the risk of clogging. Effective debris removal is crucial for maintaining penetration rates and preventing premature wear on the bit and buttons.

Still sounds complex? Imagine you’re selecting a bit for a tough granite formation. You’d want a body made from the highest-quality steel to withstand shock, tungsten carbide buttons that match the hardness of the rock, a face design tailored for stability, and robust flushing channels to keep things moving. Each component works in harmony to ensure the bit delivers top performance—no matter how challenging the drilling conditions.

As you explore the next section, you’ll see how different face and button designs are matched to specific rock formations, helping you make smarter choices for your next drilling project.

When you’re facing a tough drilling project, choosing the right button bit design can mean the difference between smooth progress and costly setbacks. But with so many face types and button shapes available, how do you know which one fits your rock formation best? Let’s break it down with a side-by-side comparison so you can make informed decisions and avoid trial-and-error in the field.

Imagine drilling through a hard, abrasive granite versus a fractured, medium-hard limestone. Would you use the same bit for both? Probably not. The face design of a button bit is engineered to tackle specific rock characteristics—hardness, abrasiveness, and fracture patterns—so selecting the right style is crucial for drilling efficiency and bit longevity. Here’s a detailed comparison of the most common face designs and button shapes, based on industry best practices and field-proven results.

| Design / Shape Type | Ideal Rock Condition | Primary Advantage | Key Limitation |

|---|---|---|---|

| Flat Face (with Spherical Buttons) | Hard, Abrasive, Uniform | Versatile; high wear resistance; stable in tough formations | May have slower penetration in softer or fractured rocks |

| Convex Face | Soft to Medium-Hard, Non-Abrasive | Excellent penetration rate in soft ground | Poor hole deviation control in hard formations |

| Concave Face | Medium-Hard to Hard, Fractured | Superior hole straightness and deviation control | Not ideal for highly abrasive or very hard rocks |

| DGR (Double Gauge Row) Face | Hard, Very Hard, Abrasive | Outstanding wear resistance and extended lifespan | Typically used for larger diameter bits; may be less effective in soft formations |

| Spherical Button | Hard, Abrasive, Mixed | Long service life; resists breakage in tough rock | Lower penetration rate than ballistic in softer rocks |

| Ballistic Button | Medium-Hard to Hard, Less Abrasive | Higher penetration rate; straighter hole | Shorter lifespan in highly abrasive or hard conditions |

| Parabolic Button | Hard, Abrasive | Improved impact resistance; good for dense rocks | May wear faster in highly fractured formations |

| Flat Button | Very Hard, Extremely Abrasive | Excellent stability and impact resistance | Reduced penetration in softer rocks |

Still not sure which button shape works best for your next job? Let’s put it in perspective. Spherical buttons, with their rounded shape, are the go-to for hard, abrasive rock—they’re tough, resist breakage, and keep you drilling longer. Ballistic buttons, on the other hand, feature a bullet-shaped design that bites into medium-hard rock with speed, offering a higher penetration rate and straighter holes, but they may wear out faster in tough, abrasive formations.

Choosing between these options is a lot like picking the right arcade button drill bit size for a custom cabinet—precision matters, and the wrong fit can cost you time and money. By matching your bit face and button shape to the rock conditions, you’ll notice improved efficiency, cleaner holes, and fewer unexpected bit replacements.

Ready to select the perfect bit for your unique project? In the next section, we’ll walk you through a proven framework for making the smartest bit selection every time—no guesswork required.

Ever found yourself staring at a catalog of button bits, wondering which one will actually deliver the results you need? You’re not alone. Selecting the right drilling tool can feel as precise—and as critical—as picking the exact arcade button drill bit size for a custom control panel. Get it wrong, and you risk wasted time, extra costs, and even safety hazards. Get it right, and your operation runs smoother, faster, and more efficiently.

Sounds complex? Let’s break it down into a simple, four-step process that demystifies bit selection and helps you make confident, data-driven decisions every time. Think of this as your personal checklist for choosing the perfect button bit for any drilling project:

Analyze the Rock Formation

Start by carefully assessing the ground you’ll be drilling. Is the rock hard and abrasive, like granite, or is it softer and more fractured? The hardness, abrasiveness, and structure of the formation dictate the bit’s cutting style and durability needs. For example:Tip: The more accurately you define your rock type, the more precisely you can match your bit—no different than choosing what size drill bit for arcade buttons to ensure a perfect fit.

Hard, abrasive rocks: Require robust, wear-resistant button bits—often with spherical or parabolic buttons for maximum durability.

Soft or fractured formations: Benefit from bits with ballistic or conical buttons and face designs that enhance penetration and debris removal.

Match to Your Drilling Rig

Next, consider the technical specs of your drilling rig. Does it operate at high RPM, or is it designed for high torque? The power and speed capabilities of your equipment influence which bit design will perform optimally.Just as an arcade builder chooses drill bits based on the material and drill type, matching your bit to your rig ensures efficiency and safety.

High-torque, low-RPM rigs: Pair well with heavy-duty bits designed for deep or hard rock drilling.

High-speed, high-RPM rigs: Often work best with bits that favor faster penetration in less abrasive formations.

Define Your Project Goal

Are you aiming for maximum drilling speed, or is bit longevity your priority? Sometimes, you can’t have both. Clarifying your main objective helps you balance the trade-off between rapid penetration and tool lifespan.Remember, in both arcade projects and industrial drilling, the right tool depends on your end goal.

Need speed? Choose bit designs with aggressive button shapes (like ballistic) and open face patterns that cut quickly but may wear faster.

Need endurance? Opt for bits with spherical or parabolic buttons and face designs that prioritize even wear and stability.

Select Face and Button Design

With your rock type, rig, and project goals clear, now it’s time to choose the exact face and button configuration. Refer back to the comparative table from the previous section for guidance:Precision here is as vital as picking the right arcade button drill bit size—too large or too small, and the outcome suffers.

Flat or double gauge faces: For hard, abrasive formations—maximize stability and bit life.

Concave or convex faces: For fractured or soft rocks—improve hole straightness and penetration.

Spherical buttons: Best for tough, abrasive rocks—offer durability and resistance to breakage.

Ballistic buttons: Ideal for medium-hard rocks—boost penetration speed but may wear faster.

Let’s say you’re tasked with drilling anchor holes in a medium-hard limestone formation using a mid-range hydraulic rig. By following this framework, you’d:

Identify the rock as medium-hard and moderately abrasive.

Check your rig’s specs and confirm it supports moderate RPM and torque.

Decide that bit longevity is more important than maximum speed, since downtime is costly on your site.

Choose a bit with a concave face and spherical or parabolic buttons, ensuring both hole accuracy and tool durability.

Just as arcade enthusiasts measure twice before drilling to avoid costly mistakes, drilling professionals use these steps to ensure every bit selection is a perfect fit for the job. By consistently applying this framework, you’ll notice fewer bit failures, improved productivity, and a smoother drilling experience overall.

Now that you’ve mastered the art of bit selection, it’s time to explore how proper care and maintenance can further extend the life and value of your button bits. Let’s dive into best practices for maximizing ROI in the next section.

Ever wondered why some button bits seem to last project after project, while others fail prematurely? The answer often comes down to a handful of smart maintenance habits and a keen eye for detail. Let’s break down the essential strategies that will help you get the most out of every button bit—boosting both efficiency and your bottom line.

"Proper button bit care can cut replacement costs by up to 20%, making maintenance one of the smartest investments in any drilling operation."

Imagine your bit button as the linchpin of your drilling operation. If it’s sharp, clean, and well-maintained, you’ll breeze through tough rock and avoid costly downtime. If neglected, even the toughest bit will wear out fast, leading to lost productivity and unplanned expenses. The good news? A few simple practices can make a world of difference.

Inspect After Every Use: Just like checking your car before a road trip, always examine your button bit for cracks, missing buttons, or unusual wear. Early detection of issues prevents catastrophic failures and extends tool life.

Clean Thoroughly—Skip the Chemicals: Remove rock cuttings and debris with soft brushes or air jets. Avoid harsh chemicals that can strip protective coatings and damage materials. Clean bits perform better and last longer.

Grind Regularly and Correctly: Don’t wait until the bit is dull. Adopt a routine of “early repair and less grinding”—sharpen buttons when they lose their original profile or when you notice a drop in drilling speed. Use diamond-coated grinding tools to restore the correct button shape and avoid overheating, which can damage the carbide.

Monitor Wear Patterns: Look for signs like over-drilling (flat buttons), body wash (excessive wear on the steel body), or “snakeskin” textures on the button surface. These patterns signal it’s time for maintenance—or, in some cases, replacement.

Maintain a Usage Log: Track how many meters each bit drills and note any repairs or regrinds. This proactive record-keeping helps predict when maintenance is due and prevents unexpected breakdowns.

Store Bits Properly: Keep your bits in a clean, dry, organized space. Use racks or cushioned containers to prevent damage from drops or contact with other tools.

Optimize Operating Parameters: Adjust drilling speed, pressure, and flushing rates to match rock conditions. Too much speed or pressure accelerates wear; too little reduces efficiency. Proper settings keep your button bit in peak condition.

Lubricate and Cool: Use appropriate lubricants and ensure adequate cooling to minimize friction and heat—key factors in extending bit life and maintaining performance.

Still unsure when to grind or replace a bit? Here are a few telltale signs and tips:

Grind when button wear flats reach 1/3 the button diameter or when penetration rate drops sharply.

Inspect for cracks, burns, or distorted buttons after each grinding session.

Establish a grinding schedule based on rock hardness and drilling conditions—every 5–10 holes is a solid rule of thumb for many operations. [Scribd]

By sticking to these guidelines, you’ll notice not just longer bit life, but also improved drilling speed, straighter holes, and fewer unexpected interruptions.

Of course, even the best maintenance can’t compensate for low-quality tools. That’s why it’s crucial to start with a high-quality Button Bit—like those engineered by QIDELI—designed for exceptional wear resistance and durability. Investing in premium bits from reputable suppliers means fewer replacements, lower total costs, and the confidence that your drilling operation is built on a solid foundation.

Ready to put these practices to work? Up next, we’ll tackle the most common button bit problems and show you how to troubleshoot performance issues before they derail your project.

Ever wondered why your drilling operation suddenly slows down or why your button bit doesn’t last as long as you expected? These frustrations are common in the field, but with the right troubleshooting approach, you can quickly pinpoint issues and get back on track. Let’s tackle the most frequent problems encountered with button bits and see how to solve them—so you spend less time fixing and more time drilling.

Problem: Slow Penetration Rate

What’s happening? You notice drilling progress is sluggish, even with a new bit button. This can be caused by dull or improperly sharpened buttons, excessive wear flats, or using the wrong bit design for the rock type.

Solution: Inspect the button bit for wear flats—if any button’s flat exceeds 1/3 of its diameter, it’s time to resharpen or replace it. Make sure the bit face and button shape match the rock formation (e.g., spherical for hard, abrasive rock; ballistic for softer rock). Adjust drilling parameters like pressure and RPM to suit the formation. Regular maintenance and prompt grinding are key to restoring optimal performance.

Problem: Premature Button Wear or Breakage

What’s happening? Buttons chip, crack, or wear out much faster than expected. This often results from drilling in highly abrasive or hard rock without the right bit design, excessive impact energy, or insufficient cooling and flushing.

Solution: Choose a button bit with tungsten carbide buttons and a face design engineered for your specific rock type. For abrasive rocks, use bits with enhanced abrasion resistance. Ensure adequate cooling and flushing to prevent thermal fatigue, and avoid excessive hammer settings that can accelerate wear. Monitor rotation speed to distribute wear evenly across all buttons.

Problem: Bit Body Damage (Body Wash)

What’s happening? The steel body of your bit wears away rapidly, especially around the gauge area. This is typically due to poor debris removal (flushing), drilling in fractured or loose ground, or using a new bit in unsuitable conditions.

Solution: Maximize flushing by checking air or fluid flow through the bit’s grooves and holes. Clean holes thoroughly after each drilling interval. In broken or loose formations, reserve new bits for solid ground and use older bits nearing the end of their life for challenging conditions. This approach prevents unnecessary wear on high-value tools.

Problem: Lost or Sheared Buttons

What’s happening? Buttons break off or shear above/below the bit body, often during forceful rotation against obstructions or in voids.

Solution: Avoid forcing the bit if jamming or stalling occurs—retract and clear the obstruction before advancing. Use moderate rotation and hammer pressure, especially when collaring on uneven surfaces. For persistent jams, consider using a smaller diameter bit or grinding down gauge buttons to pass through tight spots.

Problem: Uneven or Accelerated Button Wear

What’s happening? Some buttons wear out much faster than others, leading to inconsistent drilling and more frequent bit changes.

Solution: Ensure smooth, consistent bit rotation to distribute wear evenly across all buttons. Adjust drilling speed and check for proper alignment of the drilling rig. Regularly inspect and maintain your equipment to prevent mechanical issues that could cause uneven stress on the bit.

Problem: Button Bit Splitting or Cracking

What’s happening? The bit body or buttons develop cracks, often due to excessive interference between buttons, improper sharpening, or manufacturing defects.

Solution: If cracks appear between button sockets or at the base, send the bit for professional analysis and repair. Always follow recommended sharpening profiles and avoid excessive button protrusion. Conduct thorough inspections of new bits before use to catch any manufacturing flaws early.

Still stumped? Sometimes, multiple factors contribute to poor performance. Keep a log of drilling parameters, bit changes, and observed issues. Regular inspection and prompt action can prevent minor problems from becoming major setbacks. And remember—choosing the right bit button for your geology, rig, and project goals is the first step to avoiding most of these headaches.

With these troubleshooting tips, you’re better equipped to handle everyday drilling challenges. Next, let’s see how these principles work in practice with a real-world case study from the field.

When theory meets the dust and noise of a working quarry, the real test of any drilling strategy begins. Let’s walk through a practical case study that brings all the button bit selection principles together—so you can see exactly how the right choices translate to measurable results on the ground.

Scenario: Imagine you’re the site manager at a granite quarry in Southwest Nigeria, tasked with optimizing drilling operations for production blasting. Your goal: maximize penetration rates, minimize bit wear, and keep costs under control. But granite is notoriously hard and abrasive, demanding careful planning and the right bit button configuration.

Formation: Medium feldspar granite, high quartz content (abrasive), uniaxial compressive strength averaging 100 MPa, and low porosity.

Key Properties: High abrasiveness (AB-I ~5600), coarse grain size, and a circularity factor indicating angular grains—all factors known to accelerate bit wear (JME 2023).

Face Design Chosen: Drop-center (concave) face. This design offers superior hole straightness and helps control deviation in fractured granite, while also improving debris evacuation.

Button Shape: Spherical tungsten carbide buttons. Spherical buttons are preferred for hard, abrasive rock due to their high resistance to breakage and even wear distribution.

Flushing Configuration: Enhanced flushing holes to ensure efficient removal of granite cuttings, reducing the risk of body wash and overheating.

Drilling Rig: Hydraulic top-hammer rig with moderate RPM and high torque—well-matched to the selected bit configuration.

Drilling Settings: Weight on bit and rotation speed optimized for granite, balancing penetration and tool longevity.

Maintenance Protocol: Regular inspections and scheduled grinding every 8–10 holes, based on observed wear patterns and performance logs.

Penetration Rate: The chosen button bit achieved a consistent penetration rate, outperforming previous bits with less suitable face or button designs.

Bit Longevity: Wear rates were closely monitored and predicted using operational data, resulting in fewer unexpected bit failures and lower replacement costs.

Project Efficiency: Downtime due to bit changes and maintenance dropped significantly, and the quality of drilled holes improved—ensuring better blast results and smoother downstream operations.

By following a structured selection process and matching the button bit to the specific geological and operational context, the quarry team not only improved drilling efficiency but also extended the life of each bit button, demonstrating the tangible impact of best practices in the field. This real-world scenario underscores why a thoughtful approach to bit selection and proactive maintenance is key to success in any drilling project.

Next, we’ll sum up the essential takeaways and highlight why partnering with a high-quality bit supplier is the final piece in achieving drilling excellence.

After exploring the ins and outs of bit design, selection, and care, you might wonder—what’s the final step to ensure consistent drilling success? The answer is simple: partner with a manufacturer that delivers both quality and expertise. Let’s recap the essentials and see why your choice of supplier can make or break your operation.

Throughout this guide, we’ve highlighted how the right button bit—matched to your geology, rig, and project goals—can dramatically boost productivity and lower costs. But even the best selection framework and maintenance routine can’t overcome the limitations of a poorly made bit button. That’s why sourcing from a reputable supplier is critical.

Imagine you’ve done everything right: analyzed the rock, picked the perfect design, and kept your bits in top shape. If the bit itself isn’t engineered from high-grade steel and premium tungsten carbide, or if it lacks precise manufacturing and strict quality control, you’ll still face unexpected failures and rising expenses. A reliable manufacturer ensures:

Consistent Quality: Every bit meets rigorous standards, so you can trust its performance from the first hole to the last.

Advanced Materials: Only the best alloys and carbides are used—resulting in longer life and better energy transfer, even in the toughest rock (QIDELI).

Expert Support: Technical advice, fast response times, and after-sales service help you solve challenges and optimize performance.

So, how do you choose a supplier you can count on? Look for a proven track record, strict quality control, and a willingness to tailor solutions to your needs. One standout in the industry is QIDELI—a professional drilling tools manufacturer in China with over three decades of experience. Their Button Bit range is engineered for demanding applications, featuring advanced heat treatment, precise button fixation, and robust thread manufacturing. These innovations translate to exceptional wear resistance, stable performance, and a lower cost-per-meter drilled.

When you partner with a trusted supplier like QIDELI, you’re not just buying a tool—you’re investing in the success and safety of your entire operation. For professional drilling solutions that deliver on every promise, explore QIDELI’s button bit selection and experience the difference that quality makes, project after project.

A button bit is a specialized drill bit featuring tungsten carbide inserts ('buttons') designed for efficient rock breaking in industries like mining, construction, and geothermal drilling. Its robust design enables rapid penetration and durability in tough rock formations, making it essential for both rotary and percussive drilling systems.

Button bits come in various face designs and button shapes, such as flat face, convex, concave, and double gauge row, as well as spherical and ballistic buttons. Each design is tailored for specific rock conditions—flat faces with spherical buttons are ideal for hard, abrasive rocks, while convex or ballistic designs excel in softer formations. The right choice boosts drilling speed, hole accuracy, and bit lifespan.

To maximize button bit life, inspect and clean bits after each use, grind buttons regularly to maintain shape, monitor wear patterns, and keep a usage log. Proper storage and matching drilling parameters to formation type are also crucial. Investing in high-quality bits, like those from QIDELI, further enhances durability and cost-efficiency.

Rapid wear or slow drilling often results from using the wrong bit design for the rock type, insufficient maintenance, or improper drilling parameters. Check for wear flats, ensure correct button and face design, adjust speed and pressure, and maintain regular grinding. Using bits engineered for your specific conditions, such as QIDELI's, can significantly reduce these issues.

QIDELI button bits are manufactured with advanced heat treatment and premium materials, offering exceptional wear resistance, durability, and stable performance. Their commitment to quality and technical support ensures lower cost-per-meter drilled, minimized downtime, and a high return on investment for professional drilling operations.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China