Views: 0 Author: Site Editor Publish Time: 2025-11-19 Origin: Site

Recently, the tungsten market has continued its steady upward trend. Supported by tight supply, rising production costs, and strengthened market sentiment, prices of tungsten-related products have climbed sharply. Although terminal demand remains rigid, the actual pace of demand release is relatively slow. Under the high-price environment, transaction resistance is evident, and most industry participants are purchasing only as needed, with a noticeable wait-and-see attitude across the supply chain.

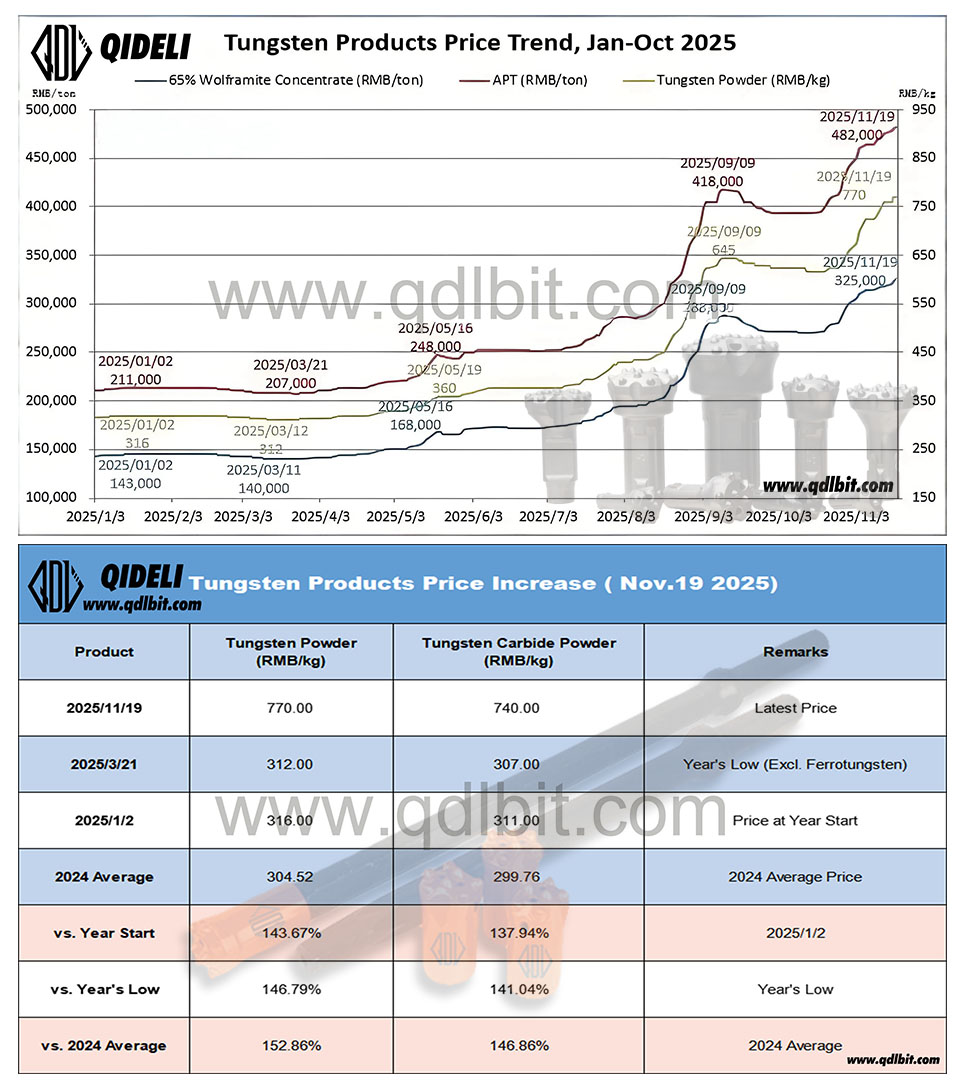

Tungsten Powder and Tungsten Carbide Powder Prices Reach New Highs

Driven by strong raw material costs, the tungsten powder market remains firm. However, limited follow-up from downstream customers has resulted in a stagnant overall trading atmosphere, with both buyers and sellers entering a stage of cautious negotiation.

Current market prices:

Tungsten powder: RMB 770/kg, up 143.7% compared with the beginning of the year.

Tungsten carbide powder: RMB 740/kg, up 137.9% since the start of the year.

The rapid price increase has intensified cost pressure across the tungsten industry chain, with a particularly significant impact on hard alloy products.

Rising Hard Alloy Costs Lead to Increased Manufacturing Costs for Drilling Tools

Tungsten carbide is the core raw material for cemented carbide. Its ongoing price surge directly elevates the manufacturing cost of hard alloy products. As an essential material in the drilling tools industry, fluctuations in its price significantly affect multiple types of drill bits, including:

DTH drill bits

Button bits

Chisel bits

Cross bits

Threaded drill bits (R25, R32, T38, T45, T51, etc.)

With raw material costs continuing to rise, drill bit manufacturers face increasing production pressures, making price adjustments an industry-wide trend. Some end-users show limited acceptance of higher prices, resulting in elongated purchasing cycles and slower procurement rhythms.

QIDELI’s Response and Industry Recommendations

As a company with more than 30 years of experience in drilling tool manufacturing, QIDELI is closely monitoring raw material market trends and actively responding to cost fluctuations through the following measures:

Optimizing raw material inventory strategies to reduce exposure to price volatility;

Enhancing manufacturing processes and improving material utilization, promoting continuous production upgrades;

Strengthening communication with upstream and downstream partners to maintain supply chain stability;

Increasing R&D investment in high-performance drill bits to counter market fluctuations through product performance advantages.

Looking ahead, changes in global mining demand, cemented carbide supply structure, and overall market sentiment will continue to influence tungsten prices. QIDELI will remain committed to delivering stable and reliable drilling products, while keeping customers informed of key market developments.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China