Views: 0 Author: Site Editor Publish Time: 2025-11-18 Origin: Site

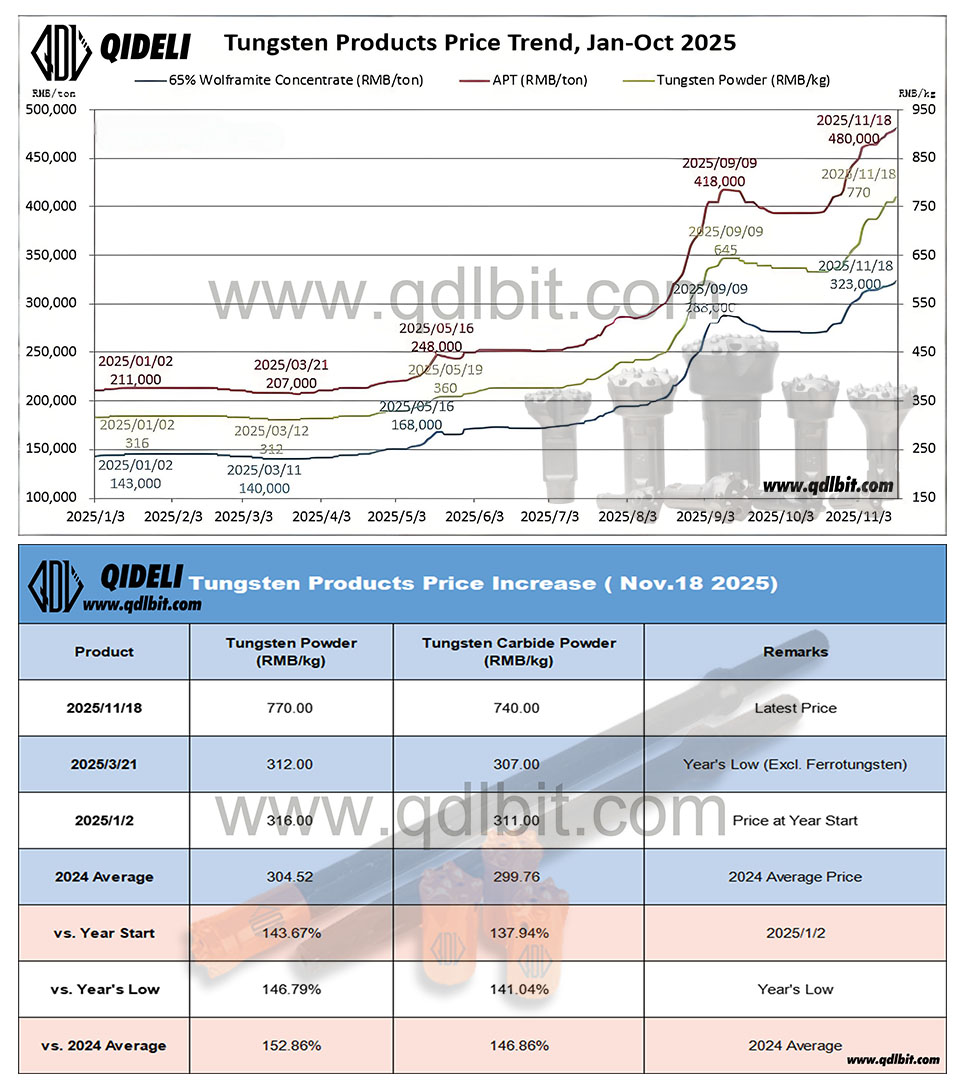

Recently, China’s tungsten market has continued its steady upward trend. Supported by tight supply and high production costs, tungsten prices remain strong. The high-price environment has somewhat suppressed market liquidity, prompting many companies to adopt on-demand and cautious purchasing strategies. Industry participants are closely watching the upcoming guidance prices from major tungsten producers to assess future market direction.

As tungsten concentrate prices continue to rise, tungsten carbide prices have also increased accordingly. As the core raw material of cemented carbide, the surge in tungsten carbide cost directly impacts the pricing of hard alloy products, placing significant pressure on the cost structure of drill bit manufacturing. Products that require a large quantity of carbide buttons—such as DTH drill bits, button bits, chisel bits, cross bits, and threaded drill bits—are experiencing noticeably higher production costs. Market prices for these products may undergo further adjustments in the near future.

Amid heightened market volatility, many manufacturing companies are optimizing inventory planning and procurement strategies to mitigate the risks brought by elevated raw material costs.

As a professional drilling tools enterprise integrating R&D, manufacturing, and sales, QIDELI Engineering Equipment closely monitors raw material market trends and actively adjusts production plans to ensure product quality and delivery stability.

We strictly select high-quality tungsten carbide and cemented carbide materials and manage costs through our in-house production system. This enables us to provide customers with:

• Stable and reliable drilling tool quality

• Competitive market pricing

• Sustainable supply capacity and on-time delivery

• A full range of drilling solutions including DTH tools, threaded drilling tools, and button bits

In response to the challenges posed by rising raw material costs, QIDELI will continue to enhance value through technological optimization, quality control, and supply chain management—delivering more reliable and cost-effective drilling products and services for customers worldwide.

Overall, the tungsten market is expected to remain at a high level in the short term, with supply tightness and cost support continuing to drive price movements. Drill tool manufacturers and end-users should closely track the price trends of tungsten carbide and cemented carbide to better plan production and procurement strategies. QIDELI Engineering Equipment will continue to provide timely industry updates to help customers make informed purchasing decisions and reduce operational risks.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China