Views: 0 Author: Site Editor Publish Time: 2026-01-16 Origin: Site

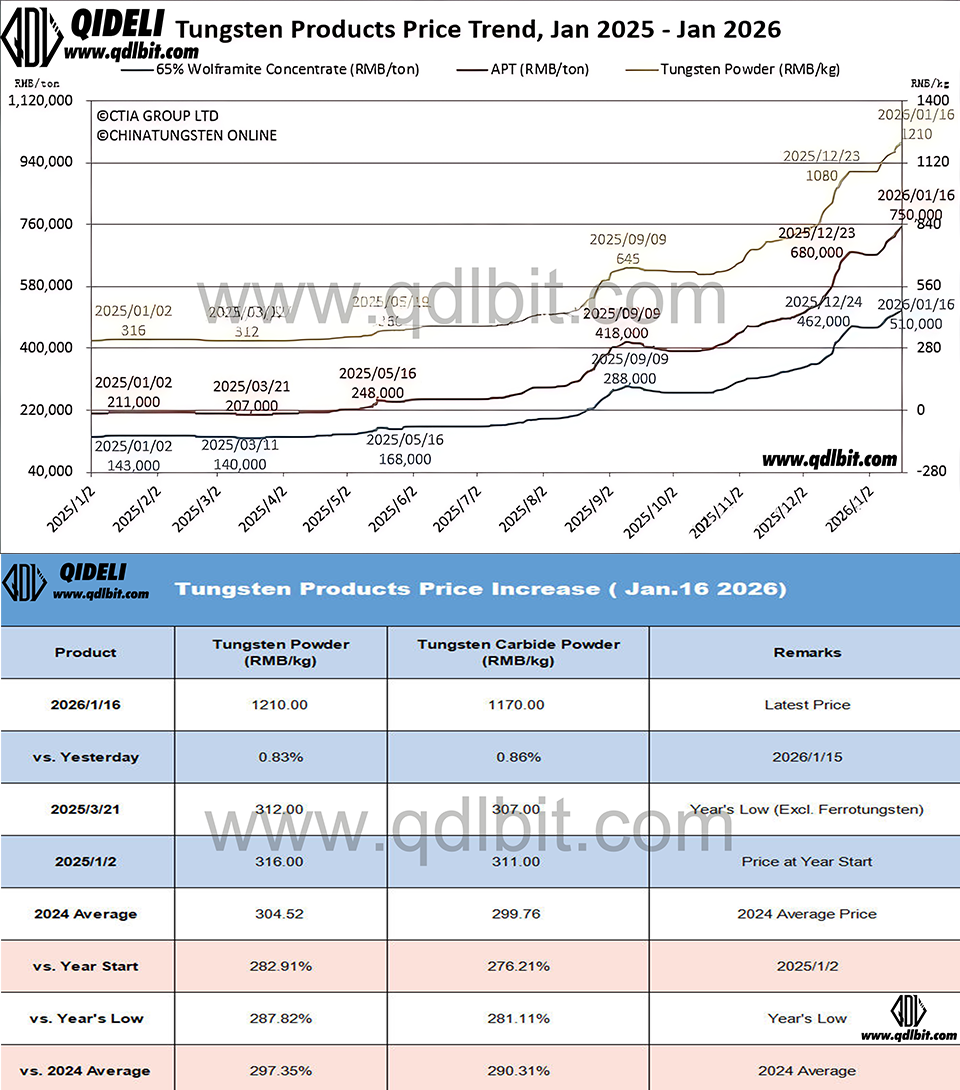

This week, the tungsten market maintained firm prices with daily fluctuations. Since the start of the year, major tungsten raw material prices have surged over 10%, exceeding key psychological levels.

Tungsten concentrate, ammonium paratungstate (APT), and tungsten powder have broken through RMB 500,000/ton, RMB 700,000/ton, and RMB 1.2 million/ton respectively.

The price uptrend is mainly driven by a tightening supply-demand balance and bullish sentiment among holders who are reluctant to sell, leading to significant cost pressures on downstream manufacturers of cemented carbide tools, special steel, and tungsten electrodes, which have been forced to adjust product prices again.

With the Spring Festival approaching, pre-holiday stocking demand has provided short-term support for tungsten product prices, but overall market liquidity is expected to cool down as the holiday atmosphere thickens.

The tungsten scrap market, sensitive to price changes, has seen slight price easing due to recent profit-taking, though firm raw material prices continue to underpin the recycling sector.

Rising Hard Alloy Costs Create Pressure for the Drilling Tools Industry

As tungsten carbide powder prices continue climbing, the cost of producing hard alloys is rising in parallel.

Tungsten carbide is one of the core materials used in the drilling tools industry, and cost increases directly affect the following products:

DTH drill bits

Button bits

Chisel bits

Cross bits

Threaded bits

PDC products that include a hard-alloy matrix

For manufacturers, high raw material prices are compressing profit margins and forcing an adjustment in product pricing structures across the industry.

QIDELI Outlook: Industry Trends in a High-Cost Era

Based on feedback across the supply chain, there is still no clear sign of price correction in the short term.

Tight resource availability, strong market sentiment, and active capital inflows together indicate that tungsten prices will remain at elevated levels.

Against this backdrop, the drilling tools industry is expected to enter:

A cost-sensitive period

A product restructuring period

A phase of rising demand for high-quality products

QIDELI will continue to closely monitor upstream raw material price changes and provide clients with timely market insights and professional guidance.

QIDELI remains committed to quality-first principles, maintaining high standards in raw material sourcing and production process control.

Even in volatile market conditions, QIDELI will ensure stable product quality and reliable supply—a promise we uphold for our global customers as we face this new industry cycle together.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China