Views: 0 Author: Site Editor Publish Time: 2025-11-20 Origin: Site

Recently, the tungsten market has maintained a steady upward trend. While prices of major tungsten products have shown mild increases, cost transmission across the industry chain remains relatively slow, and overall market transactions are still cautious. On the supply side, tungsten ore continues to exhibit a “tight supply and firm prices” pattern, with mining enterprises reluctant to sell, further pushing up raw material prices.

In the smelting sector, producers have generally raised their quotations in line with market movements. The powder market remains in a supply–demand stalemate, keeping prices stable for the moment. Meanwhile, the alloy sector is under pressure from rising upstream costs and has been compelled to increase prices, though actual transaction levels remain to be confirmed. Overall, the tungsten market is expected to remain in a structurally upward channel in the short term.

Significant Rise in Raw Material Prices: Increased Costs for Hard Alloy Production

According to the latest market quotations:

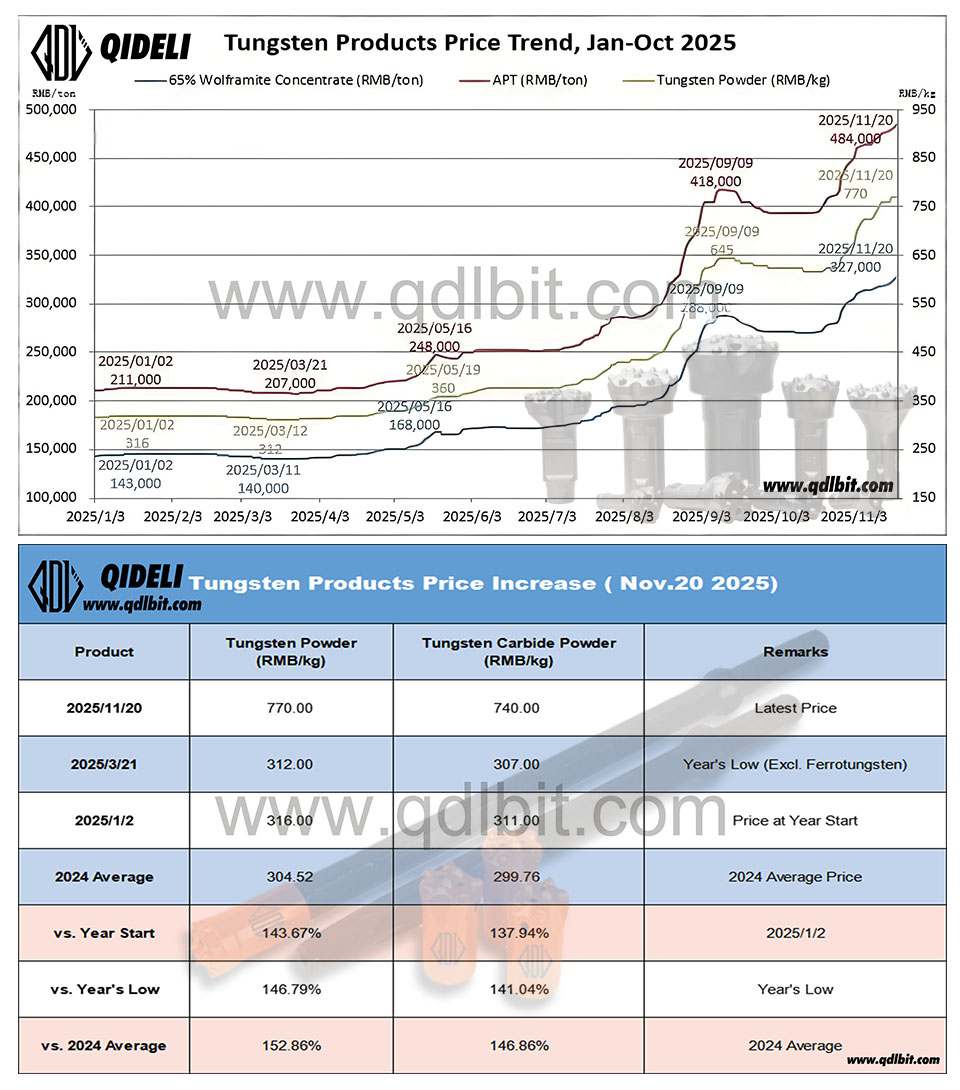

Tungsten powder is priced at around 770 RMB/kg, up 143.7% from the beginning of the year.

Tungsten carbide powder is priced at around 740 RMB/kg, an increase of 137.9% year-to-date.

As a key raw material for manufacturing hard alloys, the rapid surge in tungsten carbide powder prices has directly driven up the overall production cost of hard alloy materials.

Impact on the Drilling Tools Industry: Higher Production Costs Across Various Drill Types

Hard alloy is the most essential wear-resistant material used in DTH bits, button bits, chisel bits, cross bits, and threaded drill bits. As tungsten carbide prices continue to climb sharply, the manufacturing costs of these drill products are expected to rise substantially.

Industry observations indicate that if raw material prices remain at elevated levels, the pricing structure of drilling tools may undergo a phased adjustment. In response, manufacturers are likely to place greater emphasis on material optimization, process improvement, and inventory management to cope with the cost pressure.

QIDELI Will Continue to Monitor Market Developments

As a professional supplier of drilling tools and mining equipment, QIDELI is closely monitoring the dynamics of the tungsten market and its impact on the industry. We remain committed to maintaining transparent communication with our customers to ensure stable product supply and competitive pricing.

If you have any questions regarding these price changes or wish to discuss stocking strategies, please feel free to contact QIDELI for the latest industry insights and professional support.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China