Views: 0 Author: Site Editor Publish Time: 2025-11-12 Origin: Site

1. Tungsten Market Turns Sensitive as Supply-Demand Battle Intensifies

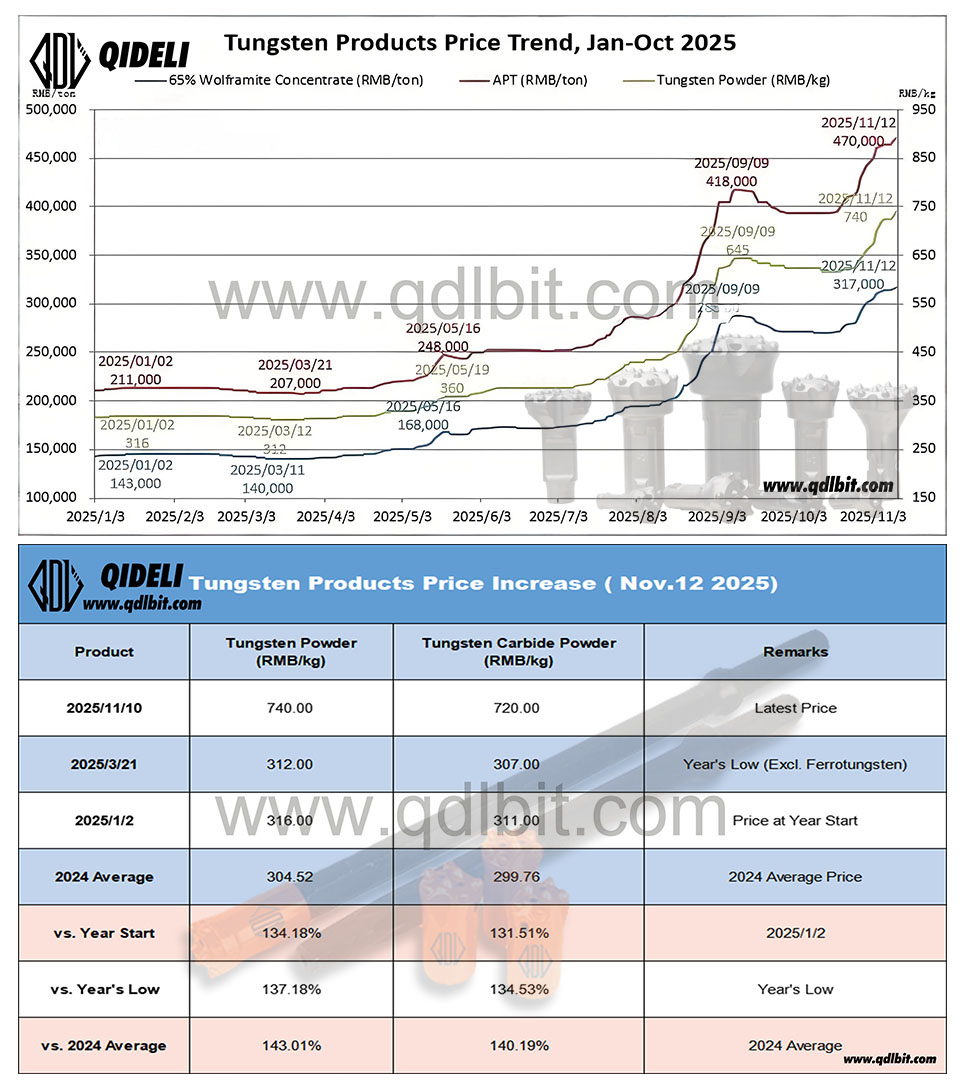

Recently, the tungsten market has entered a highly sensitive phase, with increasing price fluctuations and weak transaction activity.

• Raw material suppliers are maintaining firm quotations but showing hesitation toward further price hikes, while some are more willing to release stock.

• Consumers continue to follow an “on-demand purchasing” strategy. Although tungsten powder prices still show slight upward adjustments, downstream buyers remain cautious.

• Recycled tungsten materials show a “stable yet slightly declining” trend, with more traders choosing to close positions amid high-price stagnation.

Overall, the tungsten industry remains in a phase of tight supply-demand balance, with limited short-term breakthroughs and continued market uncertainty.

⸻

2. Cobalt Supply Disruption and Indonesia’s Emerging Resource Advantage

In the cobalt market, the government of the Democratic Republic of Congo (DRC) recently suspended a major copper-cobalt mining project operated by Huayou Cobalt’s subsidiary—Congo Dongfang International Mining in the Kolwezi region, citing leakage and environmental concerns.

This decision has heightened global fears of a potential cobalt supply shortage, adding pressure to the battery and hard alloy industries.

Meanwhile, Indonesia’s mining and processing capacity continues to expand, particularly in tungsten, cobalt, and nickel.

This trend may gradually help fill global supply gaps and stabilize the international raw material market in the coming years.

⸻

3. Rising Tungsten Carbide Costs Put Pressure on the Drilling Tool Industry

Tungsten carbide, the key material for hard alloy production, is seeing rising prices that directly affect manufacturing costs across the drilling tool industry.

Products such as DTH drill bits, button bits, chisel bits, cross bits, and threaded drill bits are experiencing noticeable cost increases.

Under this volatile raw material environment, drilling tool manufacturers are advised to:

1. Closely monitor tungsten, cobalt, and carbide market trends;

2. Optimize procurement timing and inventory strategies;

3. Improve material utilization and production efficiency to reduce per-unit cost.

⸻

4. QIDELI’s Insight: Stability Through Adaptation and Value Creation

Amid global raw material fluctuations, Qideli Engineering Equipment remains focused on market stability, cost control, and product quality.

We continuously track developments in the tungsten, cobalt, and tungsten carbide markets, refining our product structure to maintain an ideal balance between performance and cost.

Qideli is committed to providing:

• High-quality drilling tools

• Professional market insights

• Reliable and consistent supply solutions

QIDELI aim to help our partners navigate uncertainty with confidence and achieve sustainable growth in a challenging global market.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China