Views: 0 Author: Site Editor Publish Time: 2025-12-02 Origin: Site

In December 2025, China’s tungsten market continues its strong upward trajectory, demonstrating notable price resilience. Supported by supply-side disruptions and intensified market sentiment, tungsten prices remain at high levels and have become a key focus for the hard alloy and drilling tools industries.

Supply-Side Disruptions Remain the Core Driver

Recent supply fluctuations in domestic tungsten mines remain the primary force behind the rising tungsten prices. Slower mining operations and tight resource availability in certain regions have amplified raw material tension. Meanwhile, strengthened market sentiment has encouraged traders and inventory holders to adopt a firm stance, with evident reluctance to sell.

Demand Side Stable but Subdued, High Prices Suppress Restocking

Contrasting the strong supply-side influence, demand remains stable yet relatively subdued. High prices have led downstream manufacturers to adopt more cautious procurement strategies, limiting proactive restocking. Overall trading activity remains weak, with elevated costs exerting pressure on certain segments of the industry.

Year-End Timing Raises Market Sensitivity

As December progresses, the industry enters the traditional year-end stocking and financial settlement period. During this phase, both capital flow and market sentiment become increasingly sensitive.

Under the current supply–demand stalemate, industry participants largely maintain a wait-and-see attitude, with short-term attention focused on the upcoming price releases from institutions and major tungsten enterprises in Jiangxi province.

Significant Price Increases in Tungsten Powder and Tungsten Carbide

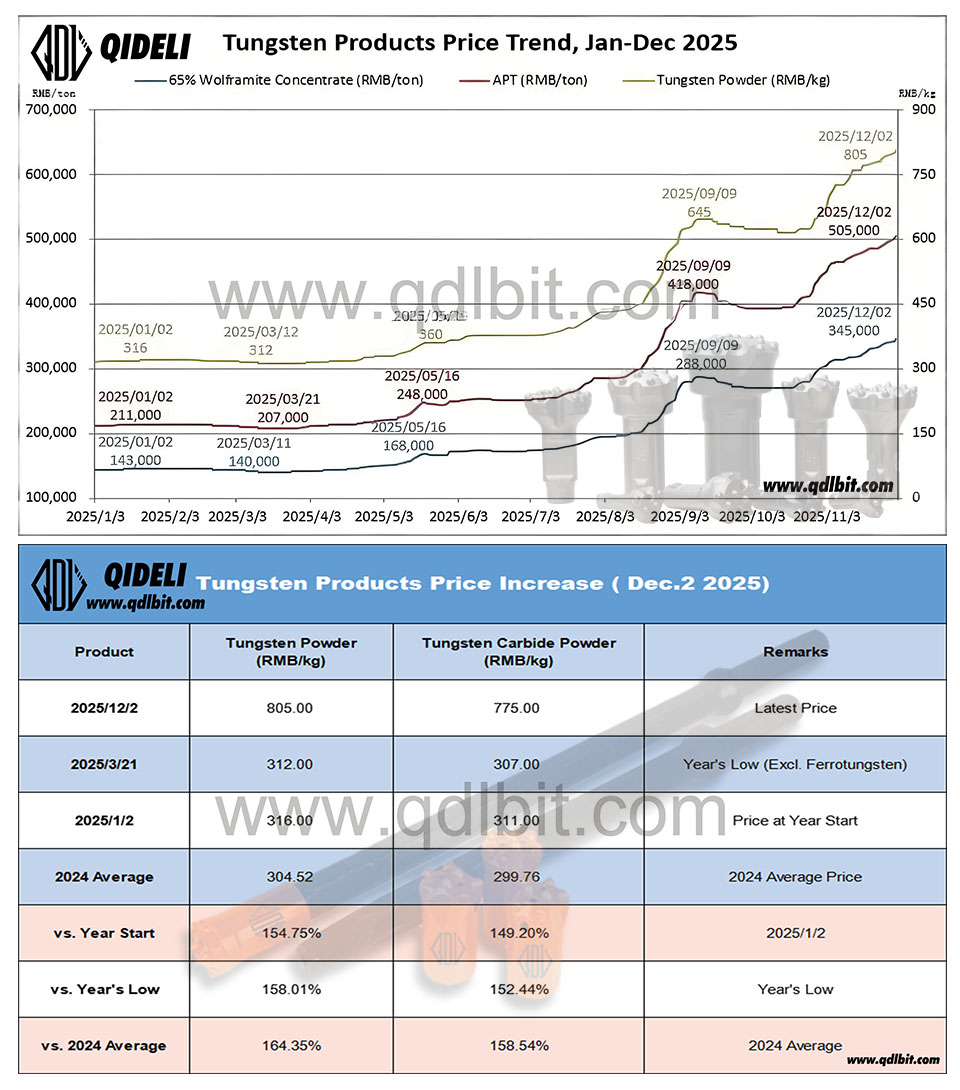

As of this report:

Tungsten powder: RMB 805/kg — up 154.8% from the beginning of the year

Tungsten carbide powder: RMB 775/kg — up 149.2% from the beginning of the year

These substantial raw material increases have placed notable cost pressure on hard alloy production.

Rising Hard Alloy Costs Impact Drilling Tools Pricing

Tungsten carbide is the core component of cemented carbide. Its price surge inevitably raises the production cost of hard alloy substrates, directly affecting the manufacturing cost of drilling tools such as:

DTH bits

Button bits

Chisel bits

Cross bits

Thread button bits

These products are expected to face continued cost pressure in the coming months.

QIDELI’s Response Strategy

As a professional drilling tools manufacturer, QIDELI is closely monitoring raw material market movements and has implemented multiple strategies to mitigate cost fluctuations:

Optimizing supply chain structure to ensure stable raw material procurement

Strengthening production process management to enhance material utilization

Planning inventory strategically to reduce risks during price volatility

Maintaining transparent communication with customers regarding market trends

Continuously improving product durability and efficiency to help customers reduce drilling cost per meter

QIDELI remains committed to stable supply capability amid industry fluctuations and will continue providing reliable, high-quality drilling tools to global customers.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China