Views: 0 Author: Site Editor Publish Time: 2025-12-01 Origin: Site

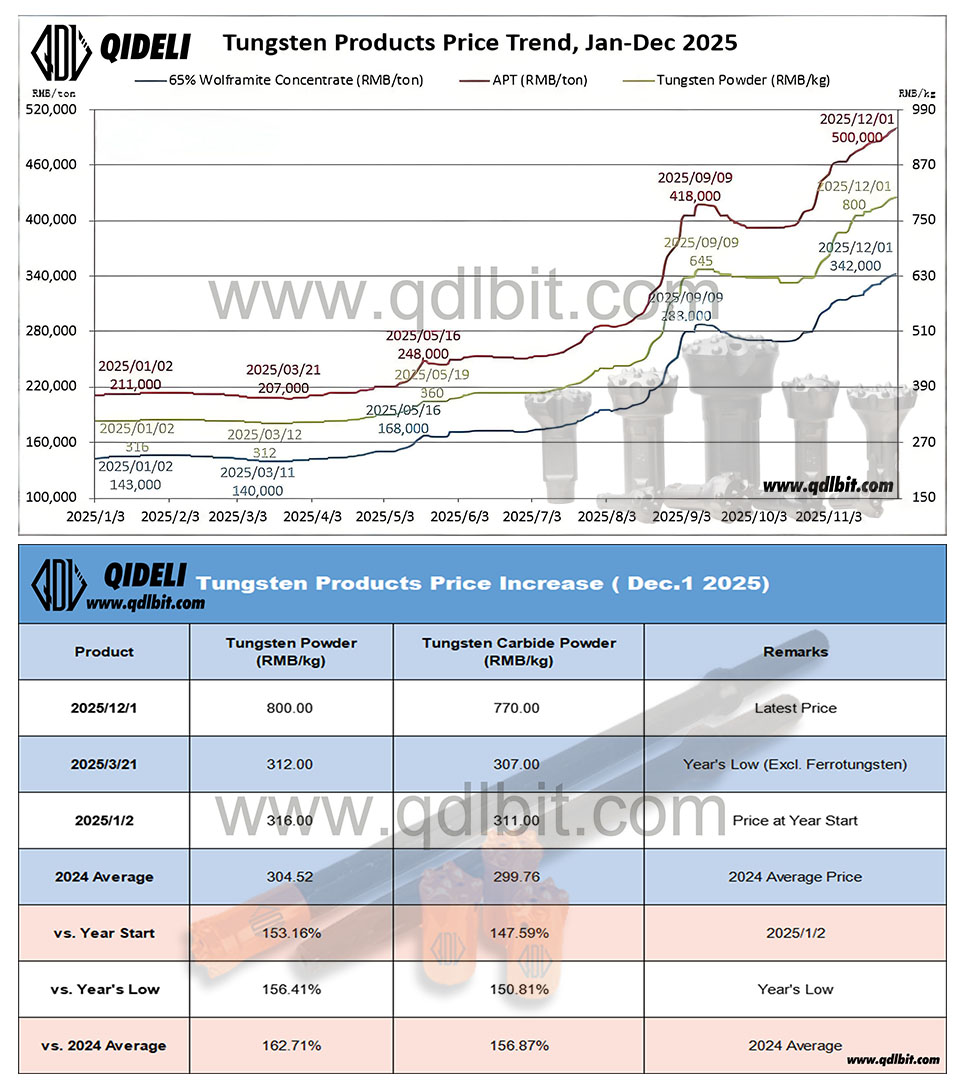

The tungsten market in 2025 has once again written a new chapter in industry history. Since the powerful upward trend began in late March, tungsten prices have continued to surge with strength, stability, and momentum far beyond expectations. As of now:

Tungsten powder has reached 800,000 RMB per ton (800 RMB/kg)

Tungsten carbide powder has risen to 770 RMB/kg

From the beginning of the year to the present, tungsten powder prices have increased by over 153%, while tungsten carbide powder has risen by over 147%. In less than four months, tungsten powder jumped from 450,000 RMB/ton to 800,000 RMB/ton — a stunning 78% increase, marking one of the most impactful price surges in the tungsten supply chain in recent years.

This round of price increases is remarkable not only for its magnitude, but also for its continuity and strong underlying logic. Each price adjustment has surpassed the previous high, forming a rare unilateral upward trend. Industry analysts widely believe that this surge is no longer driven by ordinary short-term supply–demand fluctuations, but by a strategic revaluation of tungsten as a critical resource. With limited supply growth and rising market expectations, tungsten prices are expected to remain at elevated levels.

Impact of Rising Tungsten Prices on the Drill Tools Manufacturing Industry

As the most essential raw material for cemented carbide, the continuous rise in tungsten carbide costs directly elevates manufacturing costs for drill tools. This particularly affects the following products:

DTH drill bits

Button bits

Chisel bits

Cross bits

Threaded drill bits

Various carbide components and accessories

Because carbide accounts for a significant proportion of drill bit manufacturing costs, the current price surge is reshaping pricing structures across the entire industry. The sector has officially entered a High Sensitivity Period, during which material cost fluctuations exert heightened influence on final product prices.

QIDELI’s Response and Commitment: Stable Supply · Cost Control · Reliable Delivery

Facing the ongoing surge in raw material prices, QIDELI leverages its long-term stable supply chain and large-scale production capabilities to implement the following measures, ensuring maximum value for customers:

1. Strengthened Raw Material Reserves to Mitigate Market Volatility

QIDELI establishes annual strategic reserves of tungsten powder and tungsten carbide powder to buffer short-term market fluctuations and protect customer procurement stability.

2. Optimized Material Formulations and Structural Design for High Cost-Performance

Without compromising drill bit strength, lifespan, or performance, QIDELI continuously optimizes carbide ratios and enhances material utilization efficiency.

3. Transparent Pricing Mechanisms and Market Alert Services

We will continue to publish industry updates through our official website, helping customers plan purchasing strategies in advance and avoid passive cost increases.

4. Guaranteed Delivery Timelines and Stable Quality

Even during periods of extreme cost fluctuation, QIDELI remains committed to consistent quality, rigorous manufacturing standards, and on-time delivery.

Is 1,000 RMB/kg the Next Stop for Tungsten Powder?

With 800 RMB/kg already becoming reality, the market widely anticipates the possibility of tungsten powder reaching 1,000 RMB/kg.

Given persistent supply constraints, further price increases cannot be ruled out.

Regardless of future market developments, QIDELI will continue to stand alongside our customers—navigating industry cycles and moving forward with confidence and stability.

Putian Qideli Engineering Equipment Co.,Ltd. is responsible for Qideli's self-ownedexport business. We start international business in 2017.

No.19, Houdong, Dongpuyu, Xindu, Licheng District, Putian, Fujian, China